Description

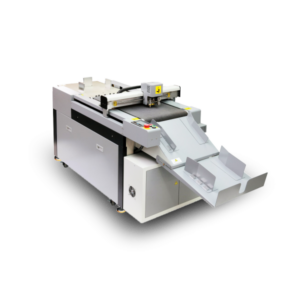

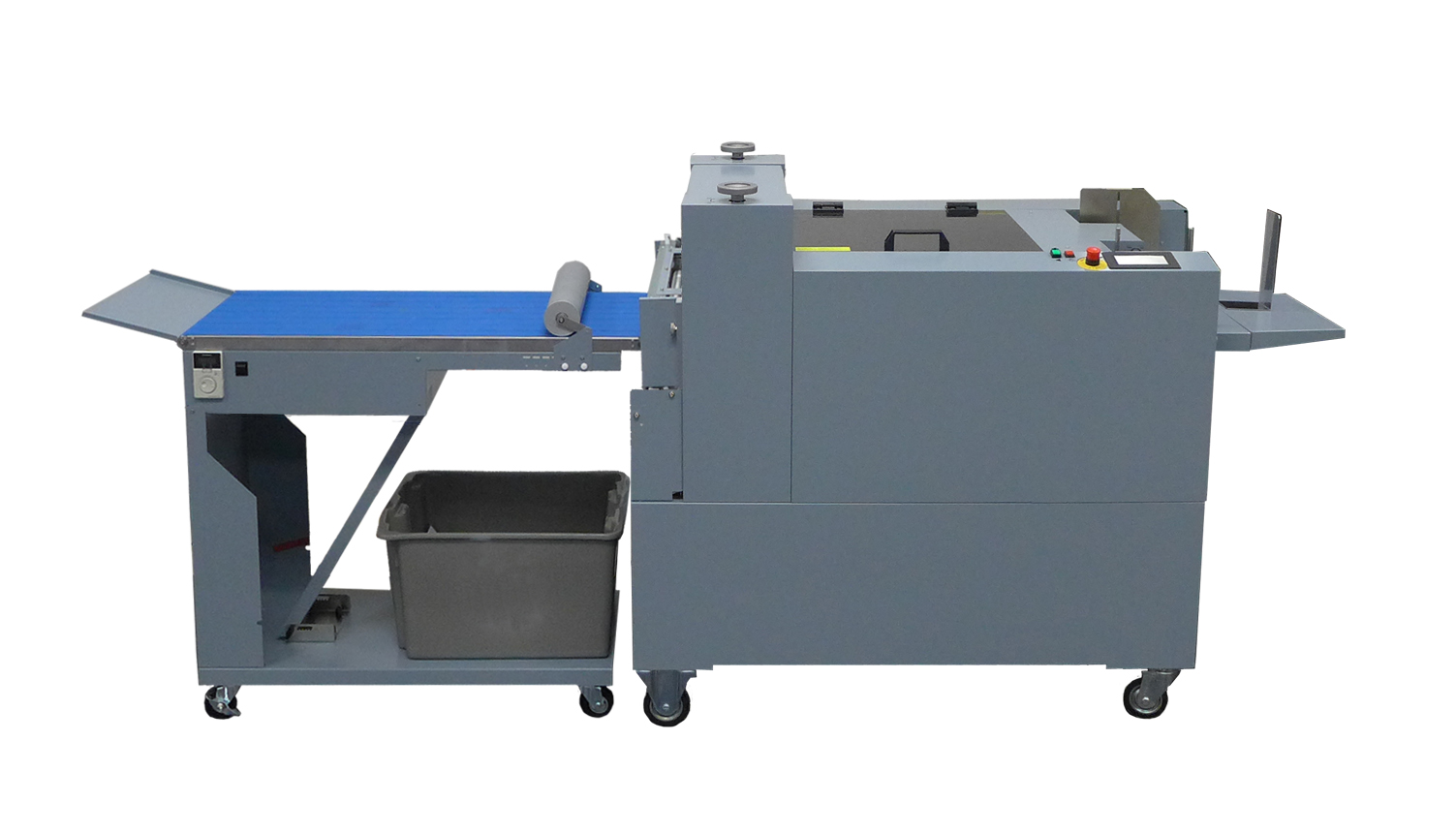

The LST - 806 cuts, kiss cuts and scores a range of substrates including paper, laminates, adhesives and synthetic stocks up to 800 x 600mm (31” x 23”). Integrated with cutting tools, creasing wheel tool, plotting pen and CCD registration system, LST - 806 digitally cut labels of any shape, folding cartons of any structure.

Designed for short run on-demand production, the LST-0806 can also be automated by QR code recognition function for auto retrieving cutting files. Takes only 15-70 seconds to finish a A3-B2 sheet (depends on complexity of shapes).

Applications include: Cardboard, Stickers, PVC, Solid grey board, corrugated board,

foam board ≤6mm etc.

FEATURES

- No physical dies required.

- Affordable, versatile solution for short-run production, Sample making, Prototyping designs (irregular shapes) Automated material feeding system

- Easy job preparation & set-up

- CCD camera QR Code automatic registration system

- Compact cutting heads

SPECIFICATIONS:

Function: Through cutting/Kiss cutting/Creasing/Plotting

Max Speed: 1200mm/s

Max Cutting Thickness: ≤6.0mm

Cutting Media: Card paper, Coated paper, Adhesive PVC, Plastic boards, PVC boards, PU, Cardboard, Fibrous boards, Rubber Sheets, marking films and corrugated board etc. Blades, Wheel: Special tungsten carbide blade/Creasing tool, electric oscillating tool. Media feeding Method:Vacuum suction

Repeat Precision: ≤0.1mm

Interface: Ethernet port

File Format: HP-GL compatible format (PLT), DXF, XML, CF2

Operational Panel: Liquid crystal display panel with touch panel

Transmission system: Imported servo driver; synchronous belt

Power Supply: AC 220V +/- 10%, 50HZ / 60HZ

Power: 4KW

Working Environment: 10 to 35 deg.C

Effective Cutting Area: 800mm x 600mm

Dimensions: 3200mm x 1100mm x 1100mm